ADL extruders are manufactured with quality materials and components, for outputs from 50 kg / h to 1,000 kg / h, with or without degassing, they are indicated for the processing of different types of polymers and compounds.

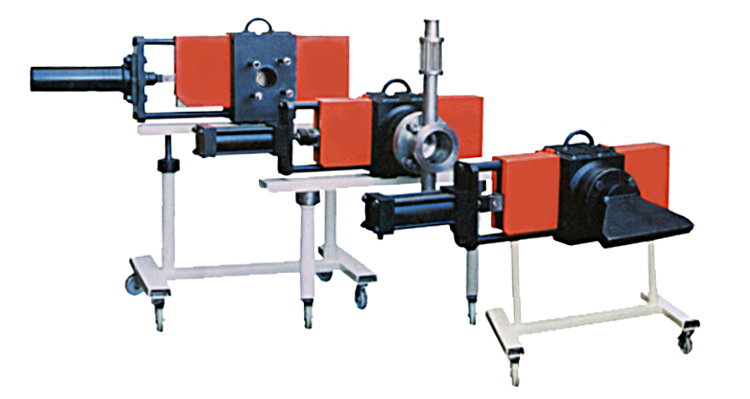

The cascade extrusion system is indicated for the processing of polymers that generate many gases during their plasticization, especially printed films.

ADL extruders with forced feeding are indicated for the processing of films or materials with low volumetric density, eliminating the use of agglomerators.

O granulador corte na cabeça ADL é uma solução indispensável para agregar valor ao produto, automatizar o processo e diminuir custos operacionais. Proporciona ainda diversas outras vantagens como: diminuição de perdas com quebras, trocas de tela sem paradas, grãos em formato esférico e redução do espaço físico utilizado.

ADL underwater pelletizers are characterized by the reliability and the long life of their rotors without sharpening.

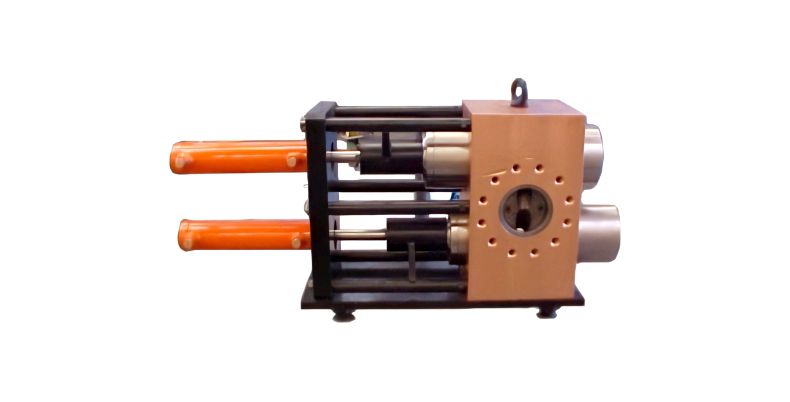

ADL hydraulic filter-change line is made up of several sizes that can be adapted to extrusion systems for sheets, tubes, multifilaments, films etc.

The ADL continuous filter-changer allows the exchange of screens without interrupting the flow of the polymer.

The ADL spaghetti dryer is a device used to assist the drying of spaghetti from the bathtub before reaching the strand pelletizer.

The ADL bagging scale is built with carbon or stainless steel silo, a practical and safe alternative to automate the bagging process. It can be mechanical or electronic.

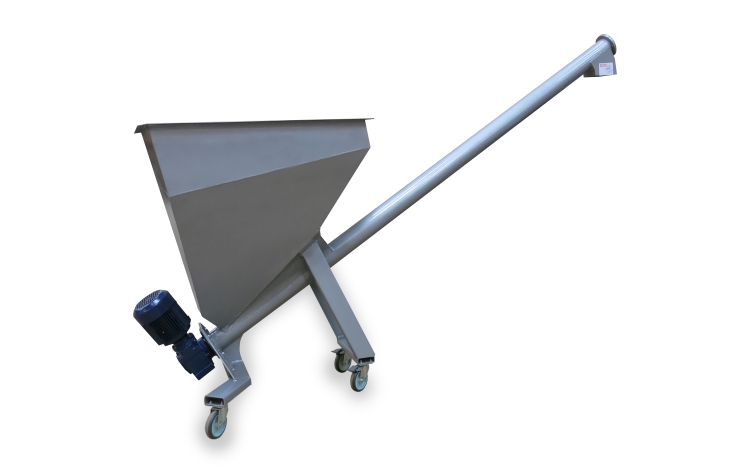

Tank with screw conveyor to automate the extrusion line feeding. Equipped with frequency inverter.

Contact our sales department through the contact form to know our availability of used machines and equipment.

Rua Lurdes Tonelli Bassetto, 59

Domingos Lopes

+55 14 3815 1761

+55 11 93459 1761

vendas@adlbtu.com.br